Galactaric acidCAS# 526-99-8 |

Quality Control & MSDS

3D structure

Package In Stock

Number of papers citing our products

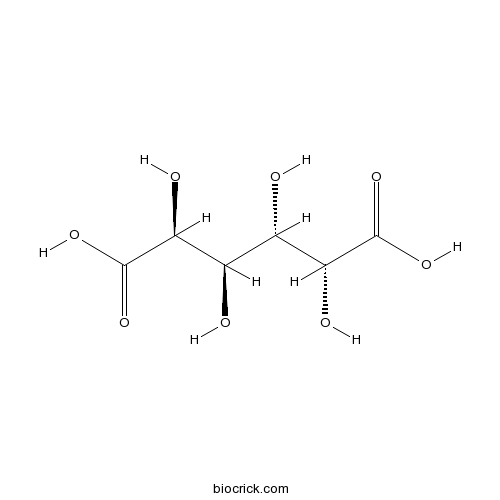

| Cas No. | 526-99-8 | SDF | Download SDF |

| PubChem ID | 3037582 | Appearance | Powder |

| Formula | C6H10O8 | M.Wt | 210.14 |

| Type of Compound | Aliphatic Compounds | Storage | Desiccate at -20°C |

| Solubility | Soluble in Chloroform,Dichloromethane,Ethyl Acetate,DMSO,Acetone,etc. | ||

| Chemical Name | (2S,3R,4S,5R)-2,3,4,5-tetrahydroxyhexanedioic acid | ||

| SMILES | C(C(C(C(=O)O)O)O)(C(C(=O)O)O)O | ||

| Standard InChIKey | DSLZVSRJTYRBFB-DUHBMQHGSA-N | ||

| Standard InChI | InChI=1S/C6H10O8/c7-1(3(9)5(11)12)2(8)4(10)6(13)14/h1-4,7-10H,(H,11,12)(H,13,14)/t1-,2+,3+,4- | ||

| General tips | For obtaining a higher solubility , please warm the tube at 37 ℃ and shake it in the ultrasonic bath for a while.Stock solution can be stored below -20℃ for several months. We recommend that you prepare and use the solution on the same day. However, if the test schedule requires, the stock solutions can be prepared in advance, and the stock solution must be sealed and stored below -20℃. In general, the stock solution can be kept for several months. Before use, we recommend that you leave the vial at room temperature for at least an hour before opening it. |

||

| About Packaging | 1. The packaging of the product may be reversed during transportation, cause the high purity compounds to adhere to the neck or cap of the vial.Take the vail out of its packaging and shake gently until the compounds fall to the bottom of the vial. 2. For liquid products, please centrifuge at 500xg to gather the liquid to the bottom of the vial. 3. Try to avoid loss or contamination during the experiment. |

||

| Shipping Condition | Packaging according to customer requirements(5mg, 10mg, 20mg and more). Ship via FedEx, DHL, UPS, EMS or other couriers with RT, or blue ice upon request. | ||

Galactaric acid Dilution Calculator

Galactaric acid Molarity Calculator

| 1 mg | 5 mg | 10 mg | 20 mg | 25 mg | |

| 1 mM | 4.7587 mL | 23.7937 mL | 47.5873 mL | 95.1746 mL | 118.9683 mL |

| 5 mM | 0.9517 mL | 4.7587 mL | 9.5175 mL | 19.0349 mL | 23.7937 mL |

| 10 mM | 0.4759 mL | 2.3794 mL | 4.7587 mL | 9.5175 mL | 11.8968 mL |

| 50 mM | 0.0952 mL | 0.4759 mL | 0.9517 mL | 1.9035 mL | 2.3794 mL |

| 100 mM | 0.0476 mL | 0.2379 mL | 0.4759 mL | 0.9517 mL | 1.1897 mL |

| * Note: If you are in the process of experiment, it's necessary to make the dilution ratios of the samples. The dilution data above is only for reference. Normally, it's can get a better solubility within lower of Concentrations. | |||||

Calcutta University

University of Minnesota

University of Maryland School of Medicine

University of Illinois at Chicago

The Ohio State University

University of Zurich

Harvard University

Colorado State University

Auburn University

Yale University

Worcester Polytechnic Institute

Washington State University

Stanford University

University of Leipzig

Universidade da Beira Interior

The Institute of Cancer Research

Heidelberg University

University of Amsterdam

University of Auckland

TsingHua University

The University of Michigan

Miami University

DRURY University

Jilin University

Fudan University

Wuhan University

Sun Yat-sen University

Universite de Paris

Deemed University

Auckland University

The University of Tokyo

Korea University

- (±)-Nicotine

Catalog No.:BCN9030

CAS No.:22083-74-5

- Cynatratoside C

Catalog No.:BCN9029

CAS No.:

- Byakangelicin

Catalog No.:BCN9028

CAS No.:482-25-7

- Neolancerin

Catalog No.:BCN9027

CAS No.:117221-65-5

- (-)-Carvone

Catalog No.:BCN8949

CAS No.:6485-40-1

- Cyanidin-3-O-(6''-malonylglucoside) chloride

Catalog No.:BCN9026

CAS No.:171828-62-9

- Sipeimine-3-beta-D-glucoside

Catalog No.:BCN9025

CAS No.:67968-40-5

- Robinetinidin chloride

Catalog No.:BCN9024

CAS No.:3020-09-5

- (+)-Mediresinol Di-O-beta-D-glucopyranoside

Catalog No.:BCN9023

CAS No.:88142-63-6

- Peonidin-3,5-O-diglucoside chloride

Catalog No.:BCN9022

CAS No.:132-37-6

- Guibourtinidin chloride

Catalog No.:BCN9021

CAS No.:23130-31-6

- Regaloside A

Catalog No.:BCN9020

CAS No.:114420-66-5

- Anethole, trans-

Catalog No.:BCN9032

CAS No.:4180-23-8

- Cichoric acid

Catalog No.:BCN9033

CAS No.:6537-80-0

- Isopongachromene

Catalog No.:BCN9034

CAS No.:

- 1-Naphthaleneacetic acid

Catalog No.:BCN9035

CAS No.:86-87-3

- Kizuta saponin K11

Catalog No.:BCN9036

CAS No.:97240-03-4

- D-(+)-Lactose Monohydrate

Catalog No.:BCN9037

CAS No.:64044-51-5

- Ganoderic acid E

Catalog No.:BCN9038

CAS No.:

- Fluoranthene

Catalog No.:BCN9039

CAS No.:206-44-0

- DL-α-Tocopherol

Catalog No.:BCN9040

CAS No.:10191-41-0

- Peimisine hydrochloride

Catalog No.:BCN9041

CAS No.:900498-44-4

- (+)-Secoisolariciresinol

Catalog No.:BCN9042

CAS No.:145265-02-7

- Allocryptopine

Catalog No.:BCN9043

CAS No.:485-91-6

Metabolomic study reveals key metabolic adjustments in the xerohalophyte Salvadora persica L. during adaptation to water deficit and subsequent recovery conditions.[Pubmed:32146282]

Plant Physiol Biochem. 2020 May;150:180-195.

Water deficit severely limits productivity of plants, and pose a major threat to modern agriculture system. Therefore, understanding drought adaptive mechanisms in drought-tolerant plants is imperative to formulate strategies for development of desiccation tolerance in crop plants. In present investigation, metabolic profiling employing GC-QTOF-MS/MS and HPLC-DAD was carried out to evaluate metabolic adjustments under drought stress in the xero-halophyte Salvadora persica. The metabolite profiling identified a total of 68 metabolites in S. persica leaf, including organic acids, amino acids, sugars, sugar alcohols, hormones, and polyphenols. The results showed that higher cellular osmolality under drought stress was accompanied by accumulations of several osmoprotectants like sugars and polyols (sucrose, glucose, mannose, galactose, erythrose, sorbose, glycerol, and myoinositol), organic acids (Galactaric acid, tartaric acid, malic acid, oxalic acid, and citric acid), and amino acids (alanine, phenylalanine, tyrosine). Upregulation of ABA and JA support to achieve early drought tolerance in S. persica. Moreover, accumulation of coumarin, gallic acid, and chlorogenic acid provide antioxidative defense to S. persica. KEGG pathway enrichment analysis showed that altered metabolites were associated with starch and sucrose metabolism, galactose metabolism, inositol phosphate metabolism, and phenylalanine metabolism. While during recovery, metabolites associated with lysine biosynthesis and alanine, aspartate and glutamate metabolism were significantly altered. The results of the present study imply that coordinated regulations between various metabolites, metabolic processes, and pathways empower the xerohalophyte S. persica to adapt under drought environment. The knowledge from this study will enable the development of drought tolerance in crops using genetic engineering and breeding approaches.

Furan-2,5- and Furan-2,3-dicarboxylate Esters Derived from Marine Biomass as Plasticizers for Poly(vinyl chloride).[Pubmed:31956766]

ACS Omega. 2019 Dec 31;5(1):197-206.

Esters of furan dicarboxylic acids (DAFs) were synthesized by a one-pot reaction between marine biomass-derived Galactaric acid and bioalcohol under solvent-free conditions and were fully characterized. The catalyst amount could be reduced without loss of reaction yields using p-xylene as the material separation agent. Also, a possible mechanism was proposed for the first time. Then the properties of four DAFs as plasticizers on the poly(vinyl chloride) (PVC) matrix were investigated. The experimental results showed that DAFs exhibit competitive efficiencies of plasticization when compared to the most commercialized plasticizer, DOP. It was found that the combination of DAFs and PVC produced homogeneous smooth-surface films, indicating miscibility between them. ATR-FTIR depicted the upshift of carbonyl absorption bands after mixing with the PVC matrix, with a magnitude of at most 18-21 cm(-1). TGA, DSC, and UTM data illustrated equivalent plasticization efficiencies. Due to their small molecular weights, the investigated DAFs are more volatile. However, due to bearing an oxygen atom in the aromatic furan ring, the degree of polarization of DAFs was boosted and helped inhibit leaching into the surrounding media. In brief, these synthetic compounds have promising feasibility as biobased plasticizers. Moreover, another interesting point is that the properties of furan-2,3-dicarboxylic acid derivatives were studied for the first time and herein reported.

Sustainable Galactarate-Based Polymers: Multi-Enzymatic Production of Pectin-Derived Polyesters.[Pubmed:31614050]

Macromol Rapid Commun. 2019 Nov;40(22):e1900361.

Large amounts of agricultural wastes are rich in pectins that, in many cases, disrupt the processing of food residues due to gelation. Despite pectins being a promising sustainable feedstock for bio-based chemical production, the current pathways to produce platform molecules from this polysaccharide are hazardous and entail the use of strong acids. The present work describes a sequence of biocatalyzed reactions that involves 1) the extraction of pectin from sugar beet pulp and enzymatic recovery of galacturonic acid (GalA), followed by 2) the enzymatic oxidation of the GalA aldehyde and the recovery of Galactaric acid (GA), and 3) the biocatalyzed polycondensation of GA to obtain fully bio-based polyesters carrying lateral hydroxy functionalities. The acid-free pectin extraction is optimized using enzymes and microwave technology. The conditions for enzymatic oxidation of GalA allow the separation of the GA produced by a simple centrifugation step that leads to the enzyme-catalyzed polycondensation reactions.

Substrate-imprinted docking of Agrobacterium tumefaciens uronate dehydrogenase for increased substrate selectivity.[Pubmed:31472210]

Int J Biol Macromol. 2019 Nov 1;140:1214-1225.

Agrobacterium tumefaciens uronate dehydrogenase (AtuUdh) belongs to the short-chain dehydrogenase superfamily, specifically those acting on the CH-OH group of donor with NAD(+) or NADP(+) as acceptor. It is apparently required for the production of D-glucaric acid. AtuUdh-catalyzed reaction is reversible with dual substrate-specific activity (D-galacturonic acid and D-glucuronic acid) in nature. In our study, 34 mutants were pre-screened from 155 mutants generated from AtuUdh (wild-type) and selected 10 structurally stable mutants with increased substrate selectivity. The specificity, efficiency, and selectivity of these mutants for different substrates and cofactors were predicted from 121 docked models using a substrate-imprinted docking approach. Q14F, S36L, and S75T mutants have shown a high binding affinity to D-glucuronic acid and its substrate intermediates such as D-glucaro-1,4-lactone and D-glucaro-1,5-lactone. These mutants exhibited a low binding affinity to the substrate and cofactor required for D-Galactaric acid. D34S, N112E and S165E mutants found to show a high selectivity of D-galacturonic acid and its substrate intermediates for D-Galactaric acid production. Ser75, Ser165, and Arg174 are active residues playing an imperative role in the substrate selectivity and also contributed in the conjecture the mechanism of transition state stabilization catalyzed by AtuUdh mutants. The present approach was used to reveal the substrate binding mechanism of AtuUdh mutants for a better understanding of the structural basis for selectivity and function.

Deciphering the Resistance Mechanism of Tomato Plants Against Whitefly-Mediated Tomato Curly Stunt Virus Infection through Ultra-High-Performance Liquid Chromatography Coupled to Mass Spectrometry (UHPLC-MS)-Based Metabolomics Approaches.[Pubmed:30925828]

Metabolites. 2019 Mar 28;9(4). pii: metabo9040060.

Begomoviruses, such as the Tomato curly stunt virus (ToCSV), pose serious economic consequences due to severe crop losses. Therefore, the development and screening of possible resistance markers is imperative. While some tomato cultivars exhibit differential resistance to different begomovirus species, in most cases, the mechanism of resistance is not fully understood. In this study, the response of two near-isogenic lines of tomato (Solanum lycopersicum), differing in resistance against whitefly-mediated ToCSV infection were investigated using untargeted ultra-high-performance liquid chromatography coupled to mass spectrometry (UHPLC-MS)-based metabolomics. The responses of the two lines were deciphered using multivariate statistics models. Principal component analysis (PCA) scores plots from various time intervals revealed that the resistant line responded more rapidly with changes to the metabolome than the susceptible counterpart. Moreover, the metabolic reprogramming of chemically diverse metabolites that span a range of metabolic pathways was associated with the defence response. Biomarkers primarily included hydroxycinnamic acids conjugated to quinic acid, Galactaric acid, and glucose. Minor constituents included benzenoids, flavonoids, and steroidal glycoalkaloids. Interestingly, when reduced to the level of metabolites, the phytochemistry of the infected plants' responses was very similar. However, the resistant phenotype was strongly associated with the hydroxycinnamic acid derivatives deployed in response to infection. In addition, the resistant line was able to mount a stronger and quicker response.

Engineering Saccharomyces cerevisiae for co-utilization of D-galacturonic acid and D-glucose from citrus peel waste.[Pubmed:30498222]

Nat Commun. 2018 Nov 29;9(1):5059.

Pectin-rich biomasses, such as citrus peel and sugar beet pulp, hold promise as inexpensive feedstocks for microbial fermentations as enzymatic hydrolysis of their component polysaccharides can be accomplished inexpensively to yield high concentrations of fermentable sugars and D-galacturonic acid (D-galUA). In this study, we tackle a number of challenges associated with engineering a microbial strain to convert pectin-rich hydrolysates into commodity and specialty chemicals. First, we engineer D-galUA utilization into yeast, Saccharomyces cerevisiae. Second, we identify that the mechanism of D-galUA uptake into yeast is mediated by hexose transporters and that consumption of D-galUA is inhibited by D-glucose. Third, we enable co-utilization of D-galUA and D-glucose by identifying and expressing a heterologous transporter, GatA, from Aspergillus niger. Last, we demonstrate the use of this transporter for production of the platform chemical, meso-Galactaric acid, directly from industrial Navel orange peel waste.

Solvent-Free Method for the Copolymerization of Labile Sugar-Derived Building Blocks into Polyamides.[Pubmed:30319929]

ACS Sustain Chem Eng. 2018 Oct 1;6(10):13504-13517.

This research focuses on the preparation of biobased copolyamides containing biacetalized Galactaric acid (GalX), namely, 2,3:4,5-di-O-isopropylidene-Galactaric acid (GalXMe) and 2,3:4,5-di-O-methylene-Galactaric acid (GalXH), in bulk by melt polycondensation of salt monomers. In order to allow the incorporation of temperature-sensitive sugar-derived building blocks into copolyamides at temperatures below the degradation temperature of the monomers and below their melting temperatures, a clever selection of salt monomers is required, such that the sugar-derived salt monomer dissolves in the other salt monomers. The polymerization was investigated by temperature dependent FT-IR and optical microscopy. The structure of the obtained copolyamides was elucidated by NMR and matrix-assisted laser desorption ionization-time-of-flight (MALDI-TOF) techniques. The positive outcome of this modified polycondensation method depends on the solubility of sugar-derived polyamide salts in polyamide salts of comonomers and the difference between their melting temperatures, however does not depend on the melting temperature of the used sugar-derived monomer. A variety of comonomers was screened in order to establish the underlying mechanisms of the process.

Structure-Property Relations in New Cyclic Galactaric Acid Derived Monomers and Polymers Therefrom: Possibilities and Challenges.[Pubmed:29656477]

Macromol Rapid Commun. 2018 Jul;39(14):e1800077.

In order to fully exploit the potential of carbohydrate-based monomers, different (and some new) functionalities are introduced on Galactaric acid via acetalization, and subsequently, partially-biobased polyamides are prepared therefrom via polycondensation in the melt. Compared to nonsubstituted linear monomer, faster advancement of the reaction is observed for the different biacetal derivatives of Galactaric acid. This kinetic observation is of great significance since it allows conducting a polymerization reaction at lower temperatures than normally expected for polyamides, which allows overcoming typical challenges (e.g., thermal degradation) encountered upon polymerization of carbohydrate-derived monomers in the melt. The polymers derived from the modified Galactaric acid monomers vary in terms of glass transition temperature, thermal stability, hydrophilicity, and functionality.

Scaling up and scaling down the production of galactaric acid from pectin using Trichoderma reesei.[Pubmed:28693605]

Microb Cell Fact. 2017 Jul 11;16(1):119.

BACKGROUND: Bioconversion of D-galacturonic acid to galactaric (mucic) acid has previously been carried out in small scale (50-1000 mL) cultures, which produce tens of grams of Galactaric acid. To obtain larger amounts of biologically produced Galactaric acid, the process needed to be scaled up using a readily available technical substrate. Food grade pectin was selected as a readily available source of D-galacturonic acid for conversion to Galactaric acid. RESULTS: We demonstrated that the process using Trichoderma reesei QM6a Deltagar1 udh can be scaled up from 1 L to 10 and 250 L, replacing pure D-galacturonic acid with commercially available pectin. T. reesei produced 18 g L(-1) Galactaric acid from food-grade pectin (yield 1.00 g [g D-galacturonate consumed](-1)) when grown at 1 L scale, 21 g L(-1) Galactaric acid (yield 1.11 g [g D-galacturonate consumed](-1)) when grown at 10 L scale and 14 g L(-1) Galactaric acid (yield 0.77 g [g D-galacturonate consumed](-1)) when grown at 250 L scale. Initial production rates were similar to those observed in 500 mL cultures with pure D-galacturonate as substrate. Approximately 2.8 kg Galactaric acid was precipitated from the 250 L culture, representing a recovery of 77% of the Galactaric acid in the supernatant. In addition to scaling up, we also demonstrated that the process could be scaled down to 4 mL for screening of production strains in 24-well plate format. Production of Galactaric acid from pectin was assessed for three strains expressing uronate dehydrogenase under alternative promoters and up to 11 g L(-1) Galactaric acid were produced in the batch process. CONCLUSIONS: The process of producing Galactaric acid by bioconversion with T. reesei was demonstrated to be equally efficient using pectin as it was with D-galacturonic acid. The 24-well plate batch process will be useful screening new constructs, but cannot replace process optimisation in bioreactors. Scaling up to 250 L demonstrated good reproducibility with the smaller scale but there was a loss in yield at 250 L which indicated that total biomass extraction and more efficient DSP would both be needed for a large scale process.

Metabolically speaking: Possible reasons behind the tolerance of 'Sugar Belle' mandarin hybrid to huanglongbing.[Pubmed:28501026]

Plant Physiol Biochem. 2017 Jul;116:36-47.

Huanglongbing (HLB) is currently considered the most destructive disease of citrus. Since its spread to the Americas, HLB has killed millions of trees and caused a sharp decline in production in many citrus growing regions. With the continuous spread of HLB disease in Florida and worldwide, there is an urgent need for the development of commercial citrus cultivars with a strong tolerance to HLB. Interestingly, field observations showed that some of the recently released mandarin hybrids such as 'Sugar Belle' were tolerant to HLB. In this study, we investigated the volatile and non-volatile metabolites of greenhouse-grown 'Sugar Belle' mandarin and four of its ancestors in order to understand why 'Sugar Belle' mandarin is relatively tolerant to HLB. Leaf volatiles were directly extracted with hexane and analyzed using gas chromatography-mass spectrometry (GC-MS). Leaf polar metabolites were extracted with a mixture of methanol:water (1:1, v/v), derivatized to their trimethylsilyl ethers, and analyzed using GC-MS. Forty-seven volatile compounds and forty-two polar metabolites were detected in 'Sugar Belle' mandarin leaves and its ancestors. 'Sugar Belle' was high in several volatiles such as alpha-thujene, para-cymene, gamma-terpinene, thymol, beta-elemene, and (E)-beta-caryophyllene. Some of these volatiles, especially thymol, beta-elemene, and (E)-beta-caryophyllene are known for their anti-microbial activity. In addition, 'Sugar Belle' mandarin was the highest in synephrine, benzoic acid, ferulic acid, caffeic acid, chiro-inositol, fructose, glucose, threonic acid, saccharic acid, and Galactaric acid, and the second in threonine, malic acid, and myo-inositol compared to the ancestors. Phenolic compounds such as benzoic, ferulic, and caffeic acids may act as antibacterial agents, whereas others like sugar alcohols may protect 'Sugar Belle' mandarin from stress during pathogen attack. The tolerance of 'Sugar Belle' and other newly released mandarin hybrids should be further evaluated using greenhouse controlled studies. If tolerance of these hybrids is confirmed, they could be used to replace the traditionally susceptible cultivars.

Enhancing fungal production of galactaric acid.[Pubmed:28191588]

Appl Microbiol Biotechnol. 2017 May;101(10):4033-4040.

Galactaric (mucic) acid is a symmetrical six carbon diacid which can be produced by oxidation of galactose with nitric acid, electrolytic oxidation of D-galacturonate or microbial conversion of D-galacturonate. Both salts and the free acid of galactarate have relatively low solubility, which may create challenges for a microbial host. Galactaric acid was most soluble at pH values around 4.7 in the presence of ammonium or sodium ions and less soluble in the presence of potassium ions. Solubility increased with increasing temperature. Production of Galactaric acid by Trichoderma reesei D-161646 was dependent on temperature, pH and medium composition, being best at pH 4 and 35 degrees C. Up to 20 g L(-1) Galactaric acid were produced from D-galacturonate using a fed-batch strategy with lactose as co-substrate and both ammonium and yeast extract as nitrogen sources. Crystals of Galactaric acid were observed to form in the broth of some fermentations.

Interfacial assembly structures and nanotribological properties of saccharic acids.[Pubmed:27966690]

Phys Chem Chem Phys. 2017 Jan 4;19(2):1236-1243.

Saccharides have been recognized as potential bio-lubricants because of their good hydration ability. However, the interfacial structures of saccharides and their derivatives are rarely studied and the molecular details of interaction mechanisms have not been well understood. In this paper, the supramolecular assembly structures of saccharic acids (including Galactaric acid and lactobionic acid), mediated by hydrogen bonds O-HN and O-HO, were successfully constructed on a highly oriented pyrolytic graphite (HOPG) surface by introducing pyridine modulators and were explicitly revealed by using scanning tunneling microscopy (STM). Furthermore, friction forces were measured in the saccharic acid/pyridine co-assembled system by atomic force microscopy (AFM), revealing a larger value than a pristine saccharic acid system, which could be attributed to the stronger tip-assembled molecule interactions that lead to the higher potential energy barrier needed to overcome. The effort on saccharide-related supramolecular self-assembly and nanotribological behavior could provide a novel and promising pathway to explore the interaction mechanisms underlying friction and reveal the structure-property relationship at the molecular level.

Engineering Aspergillus niger for galactaric acid production: elimination of galactaric acid catabolism by using RNA sequencing and CRISPR/Cas9.[Pubmed:27955649]

Microb Cell Fact. 2016 Dec 12;15(1):210.

BACKGROUND: meso-Galactaric acid is a dicarboxylic acid that can be produced by the oxidation of D-galacturonic acid, the main constituent of pectin. Mould strains can be engineered to perform this oxidation by expressing the bacterial enzyme uronate dehydrogenase. In addition, the endogenous pathway for D-galacturonic acid catabolism has to be inactivated. The filamentous fungus Aspergillus niger would be a suitable strain for Galactaric acid production since it is efficient in pectin hydrolysis, however, it is catabolizing the resulting Galactaric acid via an unknown catabolic pathway. RESULTS: In this study, a transcriptomics approach was used to identify genes involved in Galactaric acid catabolism. Several genes were deleted using CRISPR/Cas9 together with in vitro synthesized sgRNA. As a result, Galactaric acid catabolism was disrupted. An engineered A. niger strain combining the disrupted galactaric and D-galacturonic acid catabolism with an expression of a heterologous uronate dehydrogenase produced Galactaric acid from D-galacturonic acid. The resulting strain was also converting pectin-rich biomass to Galactaric acid in a consolidated bioprocess. CONCLUSIONS: In the present study, we demonstrated the use of CRISPR/Cas9 mediated gene deletion technology in A. niger in an metabolic engineering application. As a result, a strain for the efficient production of Galactaric acid from D-galacturonic acid was generated. The present study highlights the usefulness of CRISPR/Cas9 technology in the metabolic engineering of filamentous fungi.