Dihydroartemisinic acidCAS# 85031-59-0 |

Quality Control & MSDS

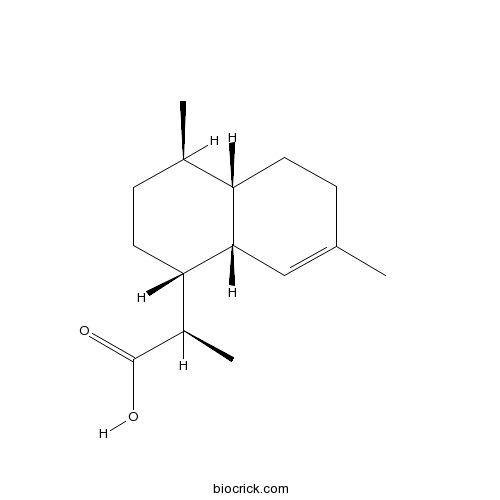

3D structure

Package In Stock

Number of papers citing our products

| Cas No. | 85031-59-0 | SDF | Download SDF |

| PubChem ID | 11020893 | Appearance | Powder |

| Formula | C15H24O2 | M.Wt | 236.35 |

| Type of Compound | Sesquiterpenoids | Storage | Desiccate at -20°C |

| Solubility | Soluble in Chloroform,Dichloromethane,Ethyl Acetate,DMSO,Acetone,etc. | ||

| Chemical Name | (2R)-2-[(1R,4R,4aS,8aS)-4,7-dimethyl-1,2,3,4,4a,5,6,8a-octahydronaphthalen-1-yl]propanoic acid | ||

| SMILES | CC1CCC(C2C1CCC(=C2)C)C(C)C(=O)O | ||

| Standard InChIKey | JYGAZEJXUVDYHI-DGTMBMJNSA-N | ||

| Standard InChI | InChI=1S/C15H24O2/c1-9-4-6-12-10(2)5-7-13(14(12)8-9)11(3)15(16)17/h8,10-14H,4-7H2,1-3H3,(H,16,17)/t10-,11-,12+,13+,14+/m1/s1 | ||

| General tips | For obtaining a higher solubility , please warm the tube at 37 ℃ and shake it in the ultrasonic bath for a while.Stock solution can be stored below -20℃ for several months. We recommend that you prepare and use the solution on the same day. However, if the test schedule requires, the stock solutions can be prepared in advance, and the stock solution must be sealed and stored below -20℃. In general, the stock solution can be kept for several months. Before use, we recommend that you leave the vial at room temperature for at least an hour before opening it. |

||

| About Packaging | 1. The packaging of the product may be reversed during transportation, cause the high purity compounds to adhere to the neck or cap of the vial.Take the vail out of its packaging and shake gently until the compounds fall to the bottom of the vial. 2. For liquid products, please centrifuge at 500xg to gather the liquid to the bottom of the vial. 3. Try to avoid loss or contamination during the experiment. |

||

| Shipping Condition | Packaging according to customer requirements(5mg, 10mg, 20mg and more). Ship via FedEx, DHL, UPS, EMS or other couriers with RT, or blue ice upon request. | ||

| Description | 1. Dihydroartemisinic acid is a precursor to the antimalarial agent artemisinin. |

Dihydroartemisinic acid Dilution Calculator

Dihydroartemisinic acid Molarity Calculator

| 1 mg | 5 mg | 10 mg | 20 mg | 25 mg | |

| 1 mM | 4.231 mL | 21.1551 mL | 42.3101 mL | 84.6203 mL | 105.7753 mL |

| 5 mM | 0.8462 mL | 4.231 mL | 8.462 mL | 16.9241 mL | 21.1551 mL |

| 10 mM | 0.4231 mL | 2.1155 mL | 4.231 mL | 8.462 mL | 10.5775 mL |

| 50 mM | 0.0846 mL | 0.4231 mL | 0.8462 mL | 1.6924 mL | 2.1155 mL |

| 100 mM | 0.0423 mL | 0.2116 mL | 0.4231 mL | 0.8462 mL | 1.0578 mL |

| * Note: If you are in the process of experiment, it's necessary to make the dilution ratios of the samples. The dilution data above is only for reference. Normally, it's can get a better solubility within lower of Concentrations. | |||||

Calcutta University

University of Minnesota

University of Maryland School of Medicine

University of Illinois at Chicago

The Ohio State University

University of Zurich

Harvard University

Colorado State University

Auburn University

Yale University

Worcester Polytechnic Institute

Washington State University

Stanford University

University of Leipzig

Universidade da Beira Interior

The Institute of Cancer Research

Heidelberg University

University of Amsterdam

University of Auckland

TsingHua University

The University of Michigan

Miami University

DRURY University

Jilin University

Fudan University

Wuhan University

Sun Yat-sen University

Universite de Paris

Deemed University

Auckland University

The University of Tokyo

Korea University

- Acetyl Perisesaccharide C

Catalog No.:BCN8666

CAS No.:110764-09-5

- Z-VDVAD-FMK

Catalog No.:BCC1138

CAS No.:N/A

- Isoboonein

Catalog No.:BCN4545

CAS No.:99946-04-0

- Bullatantriol

Catalog No.:BCN4543

CAS No.:99933-32-1

- 3-(3,4-Dihydroxyphenyl)-1-n-propylpyrrolidine hydrobromide

Catalog No.:BCN8535

CAS No.:99933-30-9

- RGD (Arg-Gly-Asp) Peptides

Catalog No.:BCC5349

CAS No.:99896-85-2

- Isoboonein acetate

Catalog No.:BCN4542

CAS No.:99891-77-7

- Kaempferol 3-O-arabinoside

Catalog No.:BCN4541

CAS No.:99882-10-7

- Droxinostat

Catalog No.:BCC2157

CAS No.:99873-43-5

- Rotigotine

Catalog No.:BCC1907

CAS No.:99755-59-6

- Scholaricine

Catalog No.:BCN4539

CAS No.:99694-90-3

- 14-Benzoylneoline

Catalog No.:BCN6493

CAS No.:99633-05-3

- Rhein-8-glucoside

Catalog No.:BCN8548

CAS No.:34298-86-7

- Cistanoside F

Catalog No.:BCN8549

CAS No.:97411-47-7

- Vinaginsenoside R3

Catalog No.:BCN8550

CAS No.:156012-92-9

- 28-Demethyl-beta-amyrone

Catalog No.:BCN8551

CAS No.:73493-60-4

- Ilexsaponin B2

Catalog No.:BCN8552

CAS No.:108906-69-0

- Trans sodium crocetinate

Catalog No.:BCN8553

CAS No.:591230-99-8

- Panasenoside

Catalog No.:BCN8554

CAS No.:31512-06-8

- Ginsenoside Ra2

Catalog No.:BCN8555

CAS No.:83459-42-1

- Uvarigranol B

Catalog No.:BCN8556

CAS No.:164204-79-9

- Rupestonic acid

Catalog No.:BCN8557

CAS No.:115473-63-7

- Dihydropalmatine

Catalog No.:BCN8558

CAS No.:26067-60-7

- Anemarrhenasaponin I

Catalog No.:BCN8559

CAS No.:163047-21-0

Production of amorphadiene in yeast, and its conversion to dihydroartemisinic acid, precursor to the antimalarial agent artemisinin.[Pubmed:22247290]

Proc Natl Acad Sci U S A. 2012 Jan 17;109(3):E111-8.

Malaria, caused by Plasmodium sp, results in almost one million deaths and over 200 million new infections annually. The World Health Organization has recommended that artemisinin-based combination therapies be used for treatment of malaria. Artemisinin is a sesquiterpene lactone isolated from the plant Artemisia annua. However, the supply and price of artemisinin fluctuate greatly, and an alternative production method would be valuable to increase availability. We describe progress toward the goal of developing a supply of semisynthetic artemisinin based on production of the artemisinin precursor amorpha-4,11-diene by fermentation from engineered Saccharomyces cerevisiae, and its chemical conversion to Dihydroartemisinic acid, which can be subsequently converted to artemisinin. Previous efforts to produce artemisinin precursors used S. cerevisiae S288C overexpressing selected genes of the mevalonate pathway [Ro et al. (2006) Nature 440:940-943]. We have now overexpressed every enzyme of the mevalonate pathway to ERG20 in S. cerevisiae CEN.PK2, and compared production to CEN.PK2 engineered identically to the previously engineered S288C strain. Overexpressing every enzyme of the mevalonate pathway doubled artemisinic acid production, however, amorpha-4,11-diene production was 10-fold higher than artemisinic acid. We therefore focused on amorpha-4,11-diene production. Development of fermentation processes for the reengineered CEN.PK2 amorpha-4,11-diene strain led to production of > 40 g/L product. A chemical process was developed to convert amorpha-4,11-diene to Dihydroartemisinic acid, which could subsequently be converted to artemisinin. The strains and procedures described represent a complete process for production of semisynthetic artemisinin.