Sulfathiazole sodiumCAS# 144-74-1 |

- Rocilinostat (ACY-1215)

Catalog No.:BCC2144

CAS No.:1316214-52-4

- LY 294002

Catalog No.:BCC3659

CAS No.:154447-36-6

- Doxorubicin

Catalog No.:BCC2082

CAS No.:23214-92-8

- E 64d

Catalog No.:BCC1127

CAS No.:88321-09-9

Quality Control & MSDS

3D structure

Package In Stock

Number of papers citing our products

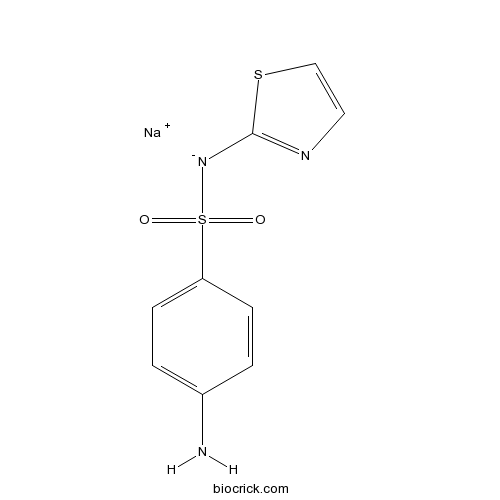

| Cas No. | 144-74-1 | SDF | Download SDF |

| PubChem ID | 12285822 | Appearance | Powder |

| Formula | C9H8N3NaO2S2 | M.Wt | 277.3 |

| Type of Compound | N/A | Storage | Desiccate at -20°C |

| Synonyms | Soluthiazomide | ||

| Solubility | DMSO : ≥ 59 mg/mL (212.77 mM) *"≥" means soluble, but saturation unknown. | ||

| Chemical Name | sodium;(4-aminophenyl)sulfonyl-(1,3-thiazol-2-yl)azanide | ||

| SMILES | C1=CC(=CC=C1N)S(=O)(=O)[N-]C2=NC=CS2.[Na+] | ||

| Standard InChIKey | GWIJGCIVKLITQK-UHFFFAOYSA-N | ||

| Standard InChI | InChI=1S/C9H8N3O2S2.Na/c10-7-1-3-8(4-2-7)16(13,14)12-9-11-5-6-15-9;/h1-6H,10H2;/q-1;+1 | ||

| General tips | For obtaining a higher solubility , please warm the tube at 37 ℃ and shake it in the ultrasonic bath for a while.Stock solution can be stored below -20℃ for several months. We recommend that you prepare and use the solution on the same day. However, if the test schedule requires, the stock solutions can be prepared in advance, and the stock solution must be sealed and stored below -20℃. In general, the stock solution can be kept for several months. Before use, we recommend that you leave the vial at room temperature for at least an hour before opening it. |

||

| About Packaging | 1. The packaging of the product may be reversed during transportation, cause the high purity compounds to adhere to the neck or cap of the vial.Take the vail out of its packaging and shake gently until the compounds fall to the bottom of the vial. 2. For liquid products, please centrifuge at 500xg to gather the liquid to the bottom of the vial. 3. Try to avoid loss or contamination during the experiment. |

||

| Shipping Condition | Packaging according to customer requirements(5mg, 10mg, 20mg and more). Ship via FedEx, DHL, UPS, EMS or other couriers with RT, or blue ice upon request. | ||

| Description | Sulfathiazole Sodium is an organosulfur compound that has been used as a short-acting sulfa drug.

Target: Antibacterial

Sulfathiazole (20 μg/L) starts to be degraded between day 31 and day 38 in one of the two batch reactors containing different wastewater matrices. Sulfathiazole is degraded at a substantially faster rate than sulfamethoxazole or sulfamethazine in the nitrification process (S3) [1]. Recovery from spiked manure slurry samples is 64% for Sulfathiazole at pH 9. Sulfathiazole has acidity constant of pKa of 7.1and retention times (tR) of 7.8. S/N values for Sulfathiazole are above 100 at the 1 mg/kg level [2]. Sulfathiazole sorption to inorganic sorbents exhibits pronounced pH dependence consistent with sorbate speciation and sorbent charge properties. Sulfathiazole cations are most important for sorption to clay minerals, followed by neutral species [3]. References: | |||||

Sulfathiazole sodium Dilution Calculator

Sulfathiazole sodium Molarity Calculator

| 1 mg | 5 mg | 10 mg | 20 mg | 25 mg | |

| 1 mM | 3.6062 mL | 18.031 mL | 36.062 mL | 72.1241 mL | 90.1551 mL |

| 5 mM | 0.7212 mL | 3.6062 mL | 7.2124 mL | 14.4248 mL | 18.031 mL |

| 10 mM | 0.3606 mL | 1.8031 mL | 3.6062 mL | 7.2124 mL | 9.0155 mL |

| 50 mM | 0.0721 mL | 0.3606 mL | 0.7212 mL | 1.4425 mL | 1.8031 mL |

| 100 mM | 0.0361 mL | 0.1803 mL | 0.3606 mL | 0.7212 mL | 0.9016 mL |

| * Note: If you are in the process of experiment, it's necessary to make the dilution ratios of the samples. The dilution data above is only for reference. Normally, it's can get a better solubility within lower of Concentrations. | |||||

Calcutta University

University of Minnesota

University of Maryland School of Medicine

University of Illinois at Chicago

The Ohio State University

University of Zurich

Harvard University

Colorado State University

Auburn University

Yale University

Worcester Polytechnic Institute

Washington State University

Stanford University

University of Leipzig

Universidade da Beira Interior

The Institute of Cancer Research

Heidelberg University

University of Amsterdam

University of Auckland

TsingHua University

The University of Michigan

Miami University

DRURY University

Jilin University

Fudan University

Wuhan University

Sun Yat-sen University

Universite de Paris

Deemed University

Auckland University

The University of Tokyo

Korea University

Sulfathiazole Sodium is an organosulfur compound that has been used as a short-acting sulfa drug.

- Zeaxanthin

Catalog No.:BCN2380

CAS No.:144-68-3

- Oxalic acid

Catalog No.:BCN8515

CAS No.:144-62-7

- Sodium bicarbonate

Catalog No.:BCC7584

CAS No.:144-55-8

- Sodium barbital

Catalog No.:BCN2160

CAS No.:144-02-5

- CTX0294885

Catalog No.:BCC6396

CAS No.:1439934-41-4

- Jaceidin triacetate

Catalog No.:BCN6245

CAS No.:14397-69-4

- CB-839

Catalog No.:BCC5493

CAS No.:1439399-58-2

- M40

Catalog No.:BCC7686

CAS No.:143896-17-7

- Elacridar hydrochloride

Catalog No.:BCC1547

CAS No.:143851-98-3

- CC-401 hydrochloride

Catalog No.:BCC1458

CAS No.:1438391-30-0

- 2,24-Dihydroxyursolic acid

Catalog No.:BCN6244

CAS No.:143839-02-5

- Fmoc-Trp(Boc)-OH

Catalog No.:BCC3558

CAS No.:143824-78-6

- Sulfamethizole

Catalog No.:BCC4856

CAS No.:144-82-1

- Sulfapyridine

Catalog No.:BCC4729

CAS No.:144-83-2

- Sodium Nitroprusside

Catalog No.:BCC4844

CAS No.:14402-89-2

- BRD73954

Catalog No.:BCC5652

CAS No.:1440209-96-0

- Piclamilast

Catalog No.:BCC6215

CAS No.:144035-83-6

- 6-O-Syringoylajugol

Catalog No.:BCN6246

CAS No.:144049-72-9

- Febuxostat

Catalog No.:BCC2556

CAS No.:144060-53-7

- Deltarasin

Catalog No.:BCC1524

CAS No.:1440898-61-2

- Deltarasin hydrochloride

Catalog No.:BCC4270

CAS No.:1440898-82-7

- Tarasaponin VII

Catalog No.:BCN2684

CAS No.:144118-18-3

- Fmoc-Asp-OAll

Catalog No.:BCC3086

CAS No.:144120-53-6

- Fmoc-Glu-OAll

Catalog No.:BCC3490

CAS No.:144120-54-7

Modification of the solid-state nature of sulfathiazole and sulfathiazole sodium by spray drying.[Pubmed:22549223]

AAPS PharmSciTech. 2012 Jun;13(2):647-60.

Solid-state characterisation of a drug following pharmaceutical processing and upon storage is fundamental to successful dosage form development. The aim of the study was to investigate the effects of using different solvents, feed concentrations and spray drier configuration on the solid-state nature of the highly polymorphic model drug, sulfathiazole (ST) and its sodium salt (STNa). The drugs were spray-dried from ethanol, acetone and mixtures of these organic solvents with water. Additionally, STNa was spray-dried from pure water. The physicochemical properties including the physical stability of the spray-dried powders were compared to the unprocessed materials. Spray drying of ST from either acetonic or ethanolic solutions with the spray drier operating in a closed cycle mode yielded crystalline powders. In contrast, the powders obtained from ethanolic solutions with the spray drier operating in an open cycle mode were amorphous. Amorphous ST crystallised to pure form I at

Compaction properties of microcrystalline cellulose and sodium sulfathiazole in combination with talc or magnesium stearate.[Pubmed:2614693]

J Pharm Sci. 1989 Dec;78(12):1025-34.

The dynamic indentation hardness, tensile strength, bonding index, and brittle fracture index were employed to investigate the compaction properties of a plastic excipient, microcrystalline cellulose, and a brittle drug, sodium sulfathiazole, in combination with different levels of either magnesium stearate or talc. These parameters were also used to quantitate properties of various combinations of microcrystalline cellulose and sodium sulfathiazole in order to illustrate the effects of combining a plastic excipient and a brittle drug. It was shown that the tensile strength, indentation hardness, bonding index, and brittle fracture index for compacts composed of microcrystalline cellulose in combination with either talc or magnesium stearate generally decreased as the amount of talc or magnesium stearate was increased over the concentration range of 0 to 9%. Similar results were observed for admixtures of sodium sulfathiazole in combination with either talc or magnesium stearate. It was also demonstrated that the tensile strength, indentation hardness, and bonding index increased, and the brittle fracture index decreased, as the percent of microcrystalline cellulose was increased in a binary mixture of sodium sulfathiazole and microcrystalline cellulose.

To evaluate the change in release from solid dispersion using sodium lauryl sulfate and model drug sulfathiazole.[Pubmed:23030270]

Drug Dev Ind Pharm. 2013 Oct;39(10):1562-72.

The solubility of drugs remains one of the most challenging aspects of formulation development. There are numerous ways to improve the solubility of drugs amongst which the most promising strategy is solid dispersion. Different ratios of sulfathiazole: PVP-K29/32: sodium lauryl sulfate (SLS) were prepared (1:1:0.1, 1:1:0.5, 1:1:1) and various methods were employed to characterize the prepared solid dispersions, namely modulated differential scanning calorimeter, X-ray powder diffraction, Fourier Transformed Infrared Spectroscopy and dissolution studies. Lack of crystallinity was observed in internal and external systems suggesting a loss of crystallinity, whereas the physical mixtures showed a characteristic peak of sulfathiazole. In vitro dissolution results clearly showed that the incorporation of a relatively small amount of surfactants (5, 20 or 33% w/w) into a solid dispersion can improve its dissolution rates compared to binary solid dispersion (SD) alone and pure sulfathiazole. In all ratios solid dispersion internal shows a higher dissolution rate compared to a physical mixture and solid dispersion external which suggests that the way that the surfactant is incorporated into the solid dispersion plays an important role in changing the solubility of a drug. The solubilization mechanism is mainly responsible for this higher dissolution rate when we incorporate the SLS in SD.